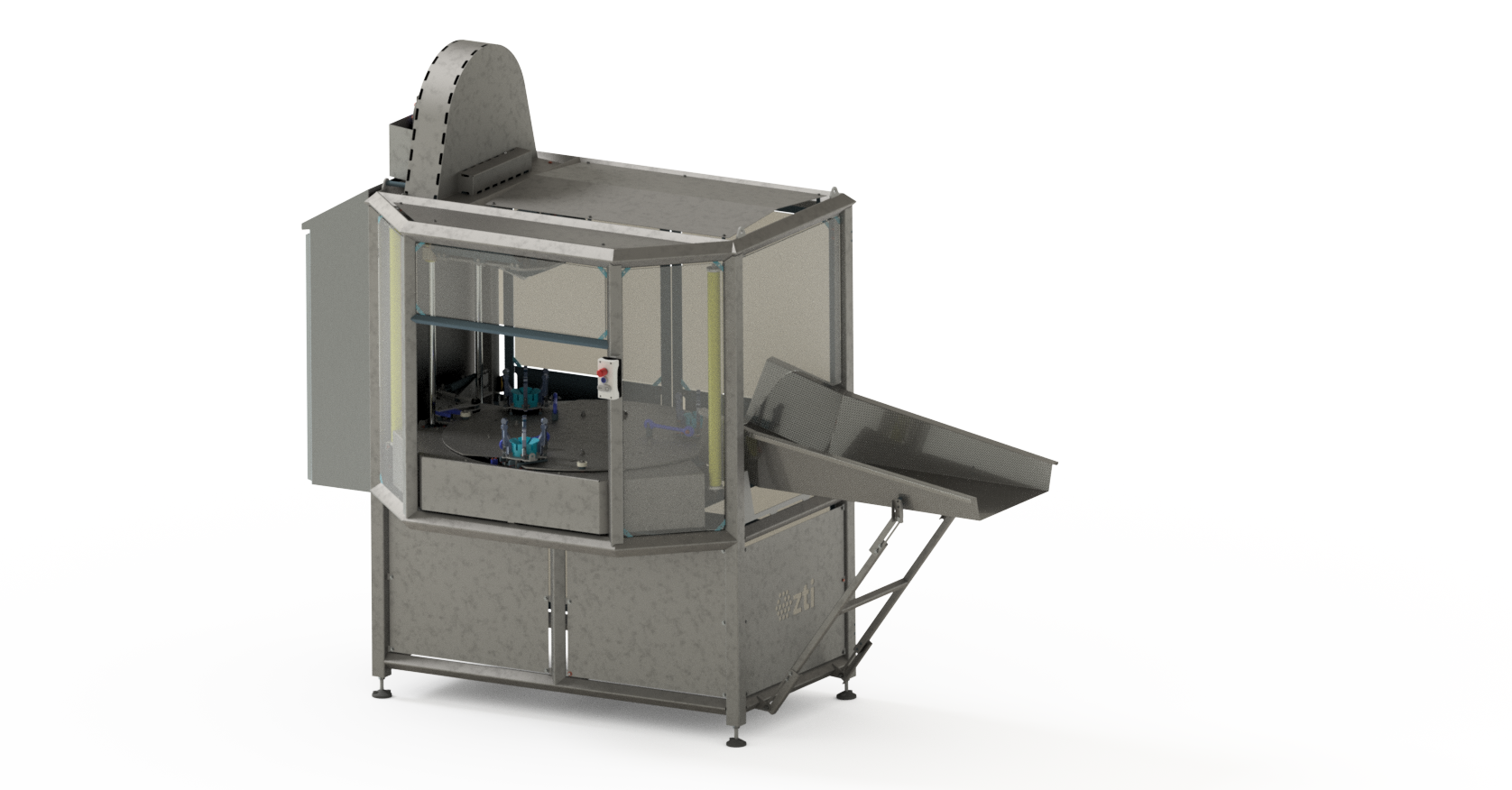

ZTI Watermelon wedger

The Watermelon Wedger is equipped with a three position turntable. The turntable moves the watermelon into the next position during processing. The fruit is manually placed on the first position. After turning to the second position the melon will be cut into two, four, six, eight, ten or twelve equal pieces. After the cutting process the table turns to the third and last position. Here the fruit is gently tilted out of the Watermelon Wedger machine and the wedges slide carefully onto a stainless steel transfer chute.

The machine operator is protected by a safety light curtain so that the blade cannot be approached during processing. When the light detects an object or a hand for example, the machine will stop immediately. The rear of the machine is equipped with two security doors that provide maximum access for maintenance and cleaning.

ENQUIRE ONLINE01449 771 202

• Special shaped wedging blade for minimal cutting forces

• Easy to operate

• Stainless steel motors

• Stainless steel E-cabinet

• Machine dimensions: L x W x H = 3000 x 1400 x 2550

• Speed: 8-12 melons per minute

• Max. product diameter 300 mm

• Max. power consumption 1kW

• Required connection for water and air 6 bar

Features of all ZTI smart fruit-processing machines

• Careful treatment and processing improves the shelf life

• High processing capacity

• Maximum yield per processed product

• Equals or betters manual processing

• Visually attractive end product

• Easy to clean and to service

• Meet European guidelines for the food-processing industry in relation to hygiene and safety

• Smart innovations that are distinguished by their simplicity

• Simple and safe to operate

• Equipped with the latest technology

• Optimum balance between ‘mechanics’ and ‘electronics’

• Attractive recovery of investment time