Pineapple peeler

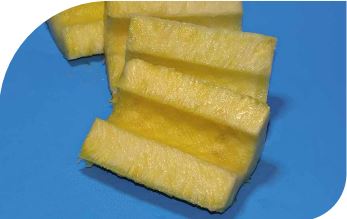

At a speed of 16 pineapples per minute, the Pineapple Peeler removes the peel from the fruit, the crown, the growing point and the core. If desired, the peeling result can have a radial slicing option into halves, quarters or a specific number of fingers. The size of the cylinder and the distance from head to tail can be accurately determined. A single machine that can take whole pineapples through several cutting and trimming stages and produce a finished product to your specification, with only a single operator required to load the machine.

MINIMAL CONTACT BETWEEN FRUIT AND PEEL

The cutting cylinder of the Pineapple Peeler makes no contact with the outside of the pineapple. Heading and tailing takes place in the first operation and only there do the blades make contact with the outside of the pineapple. The surface of the pineapple cylinder remains clean and un touched and thus minimizes the risk of contamination.

CUTTING GIVES THE BEST RESULT, LESS JUICE LOSS AND A LONGER SHELF LIFE

The machine cuts the pineapple with driven blades, instead of forcing the product through a fixed blade. This reduces juice loss and ensures a smooth cutting result. ZTI can also offer a perfect solution for processing the pineapple halves into chunks. The half pineapples fit perfectly into the trays of the ZTI Fruitcutter. This machine also cuts and treats the fruit with the utmost care, thus extending the shelf life.

• Consistent quality output

• Peeling method ensures a smooth cut

• Capacity: 16 pineapples per minute

• Diameter and length of cutting cylinders easily adjustable

• Longer blade life because the peel is minimally cut

• Minimum contact between skin and fruit

• Cylinder diameter 80 – 100 mm*

• Core diameter 20 – 35 mm*

• Cylinder length 100 – 140 mm*

• Foot print 4800x1200x2500 mm (LxWxH)

* Other product sizes can be requested

Features of all ZTI smart fruit-processing machines

• Careful treatment and processing improves the shelf life

• High processing capacity

• Maximum yield per processed product

• Equals or betters manual processing

• Visually attractive end product

• Easy to clean and to service

• Meet European guidelines for the food-processing industry in relation to hygiene and safety

• Smart innovations that are distinguished by their simplicity

• Simple and safe to operate

• Equipped with the latest technology

• Optimum balance between ‘mechanics’ and ‘electronics’

• Attractive recovery of investment time