ZTI Fruit cutter

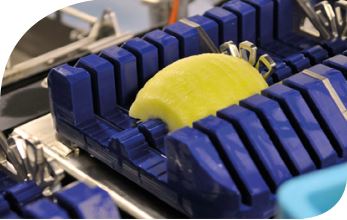

The Fruit Cutter machine slices peeled or unpeeled fruit with minimal external force. The machine is suitable for slicing and cutting pineapple, melon or peeled mango halves. In addition to its 2 stage process of producing chunks or cubes, it is also possible to use a single stage process to produce slices or fingers.

CUTTING RATHER THAN PRESSING

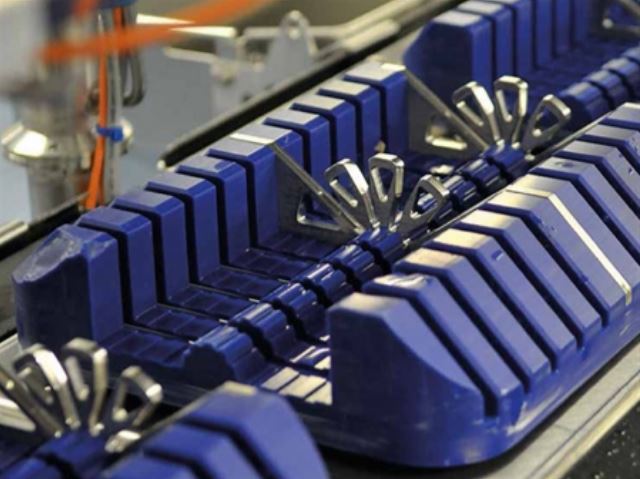

The Fruit Cutter Machine uses a system of rotating blades and so avoids forcing the fruit through stationary cutting knives. The pieces of fruit are laid in a specially-developed tray by hand. This tray ensures that the fruit remains in the same position during cutting. Once the fruit is in the tray, it is first cut lengthways. Then the tray rotates a quarter turn and the fruit is cut across (in a fan shape).

OVALS AND FINGERS

One of these cutting movements can also be left out. The fruit can then be cut into ovals or fingers. Unpeeled muskmelon is particularly suited to this. And pineapple fingers can also be cut with the Fruit Cutter.

IMPROVED SHELF LIFE

The external force that is exerted on the fruit is kept to a minimum due to the cutting action of the rotating blades. No pressure is exerted on the fruit, so it retains more of its juice. Once the fruit has been cut into pieces, the tray is carefully transferred to a conveyor belt. In this way, the cubes of fruit are subject to as little processing damage as possible, and are ready for the next stage of the process.

• The product is cut rather than pressed out

• Pieces, ovals or fingers with sharp cutting lines

• Rotating blades cut both hard and soft fruit

• Limited loss of juice

• Capacity: 40 units per minute

• Maximum diameter of fruit: 200 mm

• Dimensions of finished product: parallel blade 20 – 25

mm/radial blade 5 x 36° or 6 x 30°

• Machine dimensions: 5300 x 900 x 2500 mm (L x B x H)

Features of all ZTI smart fruit-processing machines

• Careful treatment and processing improves the shelf life

• High processing capacity

• Maximum yield per processed product

• Equals or betters manual processing

• Visually attractive end product

• Easy to clean and to service

• Meet European guidelines for the food-processing industry in relation to hygiene and safety

• Smart innovations that are distinguished by their simplicity

• Simple and safe to operate

• Equipped with the latest technology

• Optimum balance between ‘mechanics’ and ‘electronics’

• Attractive recovery of investment time