sterilAir E series

sterilAir E-series: ET Commercial UV Sanitizing Equipment is specifically designed and optimized to provide disinfection across a wide range of surfaces. This combination enables maximum effectiveness by targeting the UV-C radiation source directly onto the surface. It does not matter whether it is a conveyor belt, preparation table or the cooling coil of an evaporator.

Microorganisms can build up unwanted microbes of any kind within a few days on evaporator coils. This biofilm reduces the cooling capacity of the units and narrows the distance between the individual slats. This leads to increased energy consumption. In addition, all microbes are distributed by the air flow throughout the production area. Bacteria, yeasts and mold spores affect products, packaging and machinery. The initially clean zones are increasingly contaminated.

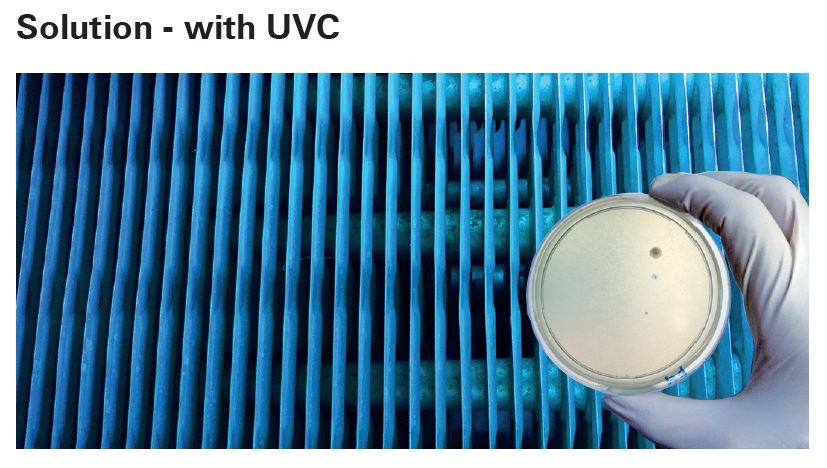

sterilAir® offers a powerful and environmentally friendly solution. Our UVC installations sustainably prevent build up and growth of biofilm. Clean coils keep energy consumption of the cooling unit constantly low. The slats remain hygienically flawless, cleaning effort and frequency decrease significantly – a considerable cost saving in operation and maintenance. The reduced airborne microbial count also minimize the risk of cross-contamination to your products. The result: improved food quality and assured shelf life data.

ENQUIRE ONLINE01449 771 202Initial situation

■ Unwanted Microorganisms

■ Growth of Biofilm

■ Risk of cross-contamination

■ Declining shelf life data

■ Product quality and safety issues

■ Increased use of chemicals

Target

■ Instant UVC disinfection 24/7

■ Constant low level microbial count

■ Improved quality

■ Secured operational safety

■ Optimized use of chemicals

■ Less cleaning efforts

Cost savings with UVC

Air conditioners and fans are often affected by biofouling due to condensate.

This leads to:

■ Germ distribution in the building, increased disease of staff

■ Higher energy demand of plant appliance

The increased energy requirement is due to a poorer heat transfer at the cooling coils as well as an increased output of the fan, which has to convey the same volume flow through a smaller opening.