Watermelon dicer

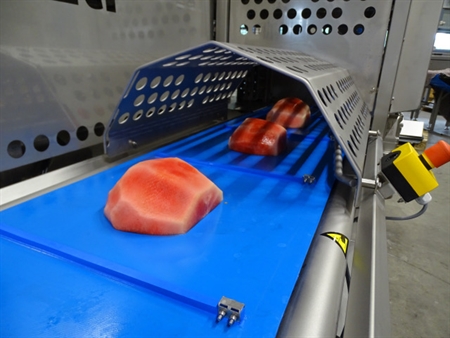

The Watermelon Dicer cuts twelve halved watermelons per minute into cubes, for example in 25 x 25 x 25 mm. The halved fruits are placed manually on the conveyor belt and transported into the machine. Product is cut cleanly and consistently into cubes. The watermelon dicer machine is safe, hygienic and robustly designed and manufactured and will automate a highly labour intensive process.

The belt positions the fruit automatically in front of the first cutting unit. Here, the fruit is guided through a combination of horizontal and vertical blades. In the second cutting unit, the fingers pass sideways rough a set of vertical blades.

LONGER SHELF LIFE AND HIGHER YIELD

The Dicer blade sets have been careful engineered to specifically handle this very delicate product. This prevents unnecessary juice loss, extends the shelf life and gives beautiful, sharply cut and evenly shaped cubes.

• Capacity: 12 products per minute

• Size cubes: 25 x 25 x 25 mm (other sizes also possible)

• Maximum product size: 300 x 300 mm

• Maximum product height: 200 mm

• Machine dimensions: ± 3200 x 2300 x 1600 mm (L x W x H)

• Stainless steel motors

• Extremely safe and fast

• Easy access through quick release belts and doors

Features of all ZTI smart fruit-processing machines

• Careful treatment and processing improves the shelf life

• High processing capacity

• Maximum yield per processed product

• Equals or betters manual processing

• Visually attractive end product

• Easy to clean and to service

• Meet European guidelines for the food-processing industry in relation to hygiene and safety

• Smart innovations that are distinguished by their simplicity

• Simple and safe to operate

• Equipped with the latest technology

• Optimum balance between ‘mechanics’ and ‘electronics’

• Attractive recovery of investment time